What is a Flame Check Machine and How Does it Function

A flame check machine helps you detect flames by sensing ultraviolet or infrared radiation. This device plays a critical role in fire safety. It activates alarms or suppression systems when it identifies a flame. By using this technology, you can reduce risks and protect industrial environments from potential hazards.

Understanding Flame Check Machines

What is a Flame Check Machine?

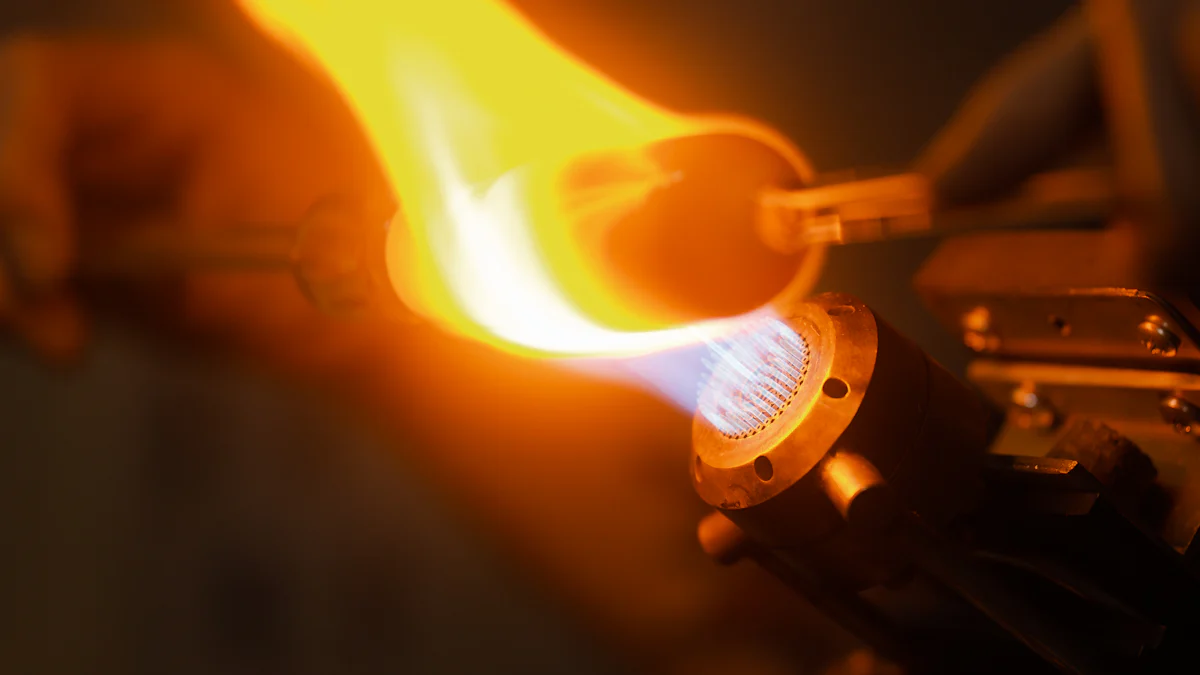

A flame check machine is a specialized device that detects flames by sensing ultraviolet (UV) or infrared (IR) radiation. It uses advanced sensors to identify the unique radiation patterns emitted by fire. This machine acts as an early warning system, helping you detect flames before they become uncontrollable.

You can think of it as a vigilant observer in environments where fire risks are high. It continuously monitors for flames and sends signals to alert you when it detects one. Some models even integrate with fire suppression systems, allowing for automatic responses. This makes the flame check machine a critical tool in fire safety.

Why Are Flame Check Machines Important?

Flame check machines play a vital role in protecting lives and property. They help you identify fire hazards quickly, reducing the chances of severe damage. In industrial settings, where flammable materials are common, these machines ensure a safer working environment.

You can rely on them to provide accurate and fast flame detection. This is especially important in places like oil refineries, chemical plants, and manufacturing facilities. Without a flame check machine, detecting a fire early becomes challenging, increasing the risk of catastrophic events. By using this technology, you enhance safety and minimize potential losses.

Tip: Regular maintenance of your flame check machine ensures it functions effectively and provides reliable protection.

How Flame Check Machines Work

Key Components of a Flame Check Machine

A flame check machine relies on several essential components to function effectively. Each part plays a specific role in detecting flames and ensuring safety. Here are the key components you should know about:

- Sensors: These are the core of the machine. They detect ultraviolet (UV) or infrared (IR) radiation emitted by flames. Some machines use both types of sensors for enhanced accuracy.

- Signal Processor: This component analyzes the data collected by the sensors. It identifies flame patterns and determines whether a fire is present.

- Alarm System: Once the machine detects a flame, the alarm system activates. It alerts you immediately, allowing you to take action.

- Control Unit: This unit manages the overall operation of the machine. It ensures that all components work together seamlessly.

- Power Supply: A reliable power source keeps the machine running continuously. Some models include backup batteries for uninterrupted operation.

These components work together to make the flame check machine a dependable tool for fire detection.

Operational Mechanism of Flame Check Machines

The operational process of a flame check machine is straightforward yet highly effective. First, the sensors continuously monitor the environment for UV or IR radiation. When they detect radiation matching the characteristics of a flame, they send a signal to the processor.

The signal processor evaluates the data to confirm the presence of a flame. If it identifies a fire, the machine triggers the alarm system. In some cases, it also activates fire suppression systems automatically. This rapid response minimizes the risk of damage and ensures safety.

You can rely on the machine to operate consistently, even in challenging conditions. Its ability to detect flames quickly makes it an essential safety device in industrial and high-risk environments.

Types and Applications of Flame Check Machines

Types of Flame Check Machines

Flame check machines come in different types, each designed for specific needs. Understanding these types helps you choose the right one for your environment. Here are the main categories:

- UV Flame Detectors: These machines detect ultraviolet radiation emitted by flames. They work well in environments with minimal sunlight or artificial UV sources.

- IR Flame Detectors: These detect infrared radiation from flames. They are ideal for areas with high ambient light or where UV interference is common.

- UV/IR Flame Detectors: These combine UV and IR sensors for enhanced accuracy. They reduce false alarms by cross-verifying flame signals.

- Multi-Spectrum IR Detectors: These advanced machines use multiple IR wavelengths to detect flames. They offer high sensitivity and are suitable for complex environments.

- CCTV Flame Detectors: These integrate cameras to visually confirm flame detection. They provide an additional layer of verification.

Each type has unique strengths. You should evaluate your specific requirements before selecting a flame check machine.

Applications in Various Industries

Flame check machines play a crucial role across many industries. Their ability to detect flames quickly makes them indispensable in high-risk settings. Here are some common applications:

- Oil and Gas: Refineries and drilling sites use these machines to monitor flammable materials and prevent fires.

- Chemical Plants: They ensure safety in environments with volatile chemicals.

- Manufacturing: Factories rely on them to protect equipment and workers from fire hazards.

- Power Generation: Power plants use them to monitor turbines and boilers for potential fires.

- Warehousing: Storage facilities with flammable goods benefit from their early detection capabilities.

- Aviation: Hangars and fuel storage areas use them to enhance fire safety.

By using a flame check machine, you can safeguard your operations and reduce fire-related risks in these industries.

Flame check machines play a key role in creating safer industrial environments. By learning how they work and where they are used, you can improve fire safety strategies. Their ability to detect flames quickly and accurately helps prevent accidents. These machines are essential for protecting both people and property in high-risk settings.