The lighter making machine industry is transforming rapidly in 2025. You see advancements that improve efficiency and redefine manufacturing processes. Staying informed about these changes helps you remain competitive. Machines like the Fully Automatic Lighter Test Machine are reshaping production standards. These innovations drive sustainability, precision, and cost-effectiveness, creating a significant impact on the industry.

Key Takeaways

- Use automation and AI to make lighter production faster. Smart systems help work better, save time, and make more lighters.

- Choose eco-friendly materials like biodegradable plastics to please buyers. This helps the planet and saves money too.

- Use IoT tools to check machines and fix problems quickly. This keeps work smooth and solves issues fast.

Automation and AI in Lighter Making Machines

Smart manufacturing for efficiency

Automation and artificial intelligence are transforming how you approach lighter production. Smart manufacturing systems now allow lighter making machines to operate with minimal human intervention. These systems analyze data in real time, optimizing production lines for maximum output. You can achieve higher efficiency by reducing downtime and eliminating repetitive manual tasks.

For example, automated assembly lines ensure consistent quality in every lighter produced. Sensors embedded in the machines monitor each step of the process. If an issue arises, the system adjusts immediately to maintain smooth operations. This level of precision not only saves time but also reduces material waste.

Smart manufacturing also enables you to scale production effortlessly. Whether you need to produce thousands of units or smaller batches, these systems adapt to your requirements. By integrating automation, you can meet market demands faster and more efficiently.

Predictive maintenance with AI

AI-powered predictive maintenance is another game-changer for lighter making machines. Instead of waiting for a machine to break down, you can now predict potential issues before they occur. AI algorithms analyze performance data from sensors installed in the machines. They identify patterns that indicate wear and tear or other problems.

This proactive approach minimizes unexpected downtime. When you address maintenance needs early, you extend the lifespan of your equipment. Predictive maintenance also lowers repair costs by preventing major failures. You can allocate resources more effectively, ensuring uninterrupted production.

With AI, you gain valuable insights into your machines’ performance. These insights help you make informed decisions, improving overall productivity. Predictive maintenance ensures your operations run smoothly, keeping you ahead in the competitive lighter manufacturing industry.

Durable and Sustainable Materials

Lightweight, eco-friendly options

The demand for sustainable manufacturing has grown significantly. You now have access to materials that are both lightweight and eco-friendly. These materials reduce the environmental impact of production while maintaining the quality of the final product. For example, biodegradable plastics and recycled metals are becoming popular choices in the industry. They allow you to create durable lighters without contributing to waste.

Using lightweight materials also improves efficiency. Machines require less energy to handle these materials, which lowers production costs. Additionally, lighter lighters are easier to transport, reducing shipping expenses and carbon emissions. By adopting eco-friendly options, you not only meet consumer expectations but also align with global sustainability goals.

Improved heat resistance

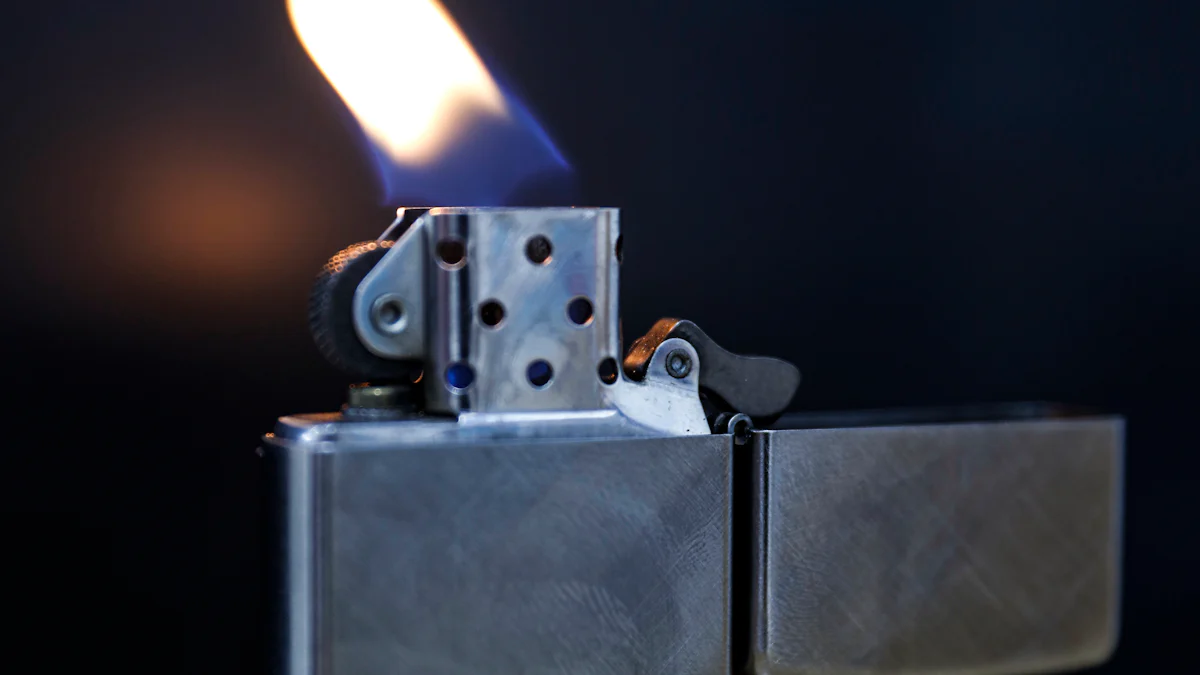

Heat resistance is a critical factor in lighter production. You need materials that can withstand high temperatures without deforming or losing functionality. Recent advancements have introduced innovative materials with enhanced heat resistance. These materials ensure the safety and reliability of your products.

For instance, ceramic composites and advanced polymers are now widely used. They provide excellent thermal stability, making them ideal for lighter components. With these materials, you can produce lighters that perform consistently under extreme conditions. This improvement also reduces the risk of product failure, enhancing customer satisfaction.

By incorporating durable and sustainable materials into your lighter making machine processes, you achieve a balance between performance and environmental responsibility. These innovations help you stay competitive in a rapidly evolving market.

Energy Efficiency in Manufacturing

Lower energy consumption

Energy efficiency has become a top priority in manufacturing. Modern lighter making machines now consume significantly less energy compared to older models. This improvement stems from advanced engineering and optimized production processes. You can reduce operational costs while maintaining high output levels.

Energy-efficient machines use innovative technologies like variable speed drives and energy recovery systems. These features adjust power usage based on real-time production needs. For example, when the machine operates at lower speeds, it automatically reduces energy consumption. This ensures that no energy goes to waste during idle periods.

By adopting energy-efficient equipment, you also contribute to environmental sustainability. Lower energy usage means fewer greenhouse gas emissions. This aligns your manufacturing practices with global efforts to combat climate change. You not only save money but also enhance your brand’s reputation as an eco-conscious business.

Use of renewable energy sources

The shift toward renewable energy sources is transforming the manufacturing landscape. Many factories now integrate solar panels, wind turbines, or other renewable systems to power their operations. You can use these sources to run your lighter making machine, reducing dependence on fossil fuels.

Renewable energy offers long-term cost savings. Once installed, systems like solar panels provide free energy for decades. This reduces your electricity bills and shields you from fluctuating energy prices. Additionally, renewable energy systems often qualify for government incentives, further lowering your investment costs.

Using renewable energy also demonstrates your commitment to sustainability. Consumers increasingly prefer brands that prioritize green practices. By powering your production with clean energy, you meet customer expectations and strengthen your market position. This approach ensures your business remains competitive in a rapidly evolving industry.

Precision and Microfabrication

High-precision components

Precision plays a critical role in modern manufacturing. With advancements in technology, lighter making machines now produce components with exceptional accuracy. These machines use cutting-edge tools like laser cutters and CNC (Computer Numerical Control) systems to achieve high precision. You can create parts that fit together perfectly, ensuring the final product functions flawlessly.

High-precision components reduce the risk of defects. When every part meets exact specifications, you avoid issues like misalignment or poor performance. This level of accuracy also improves the durability of your lighters. Customers value products that last longer and work reliably, and precision manufacturing helps you meet those expectations.

Precision also enhances efficiency. Machines waste less material when they cut or mold components with accuracy. This reduces production costs and minimizes environmental impact. By investing in high-precision technology, you can improve both your product quality and your bottom line.

Micro-level customization

Customization has become a key trend in manufacturing. Lighter making machines now offer micro-level customization, allowing you to tailor products to specific needs. Whether it’s unique designs, intricate patterns, or personalized branding, these machines make it possible to create highly detailed features.

Micro-level customization helps you stand out in a competitive market. Customers appreciate products that reflect their individuality. By offering personalized options, you can attract a wider audience and build stronger customer loyalty.

This capability also benefits small-batch production. You can produce limited-edition lighters or prototypes without significant retooling. The flexibility of microfabrication technology ensures you can adapt quickly to changing market demands. With these tools, you can deliver innovative products that meet diverse customer preferences.

IoT-Enabled Lighter Making Machines

Real-time monitoring

The Internet of Things (IoT) has revolutionized how you manage lighter production. With IoT-enabled lighter making machines, you can monitor operations in real time. Sensors embedded in these machines collect data on performance, temperature, and production speed. This data streams to a centralized dashboard, giving you a clear view of the entire process.

Real-time monitoring helps you identify inefficiencies immediately. For example, if a machine operates below optimal speed, the system alerts you. You can then take corrective action before it impacts production. This feature also ensures consistent product quality. By tracking every stage of the process, you can maintain high standards without manual oversight.

Another advantage is improved resource management. You can track energy usage, material consumption, and machine output in real time. This allows you to optimize production schedules and reduce waste. With IoT, you gain full control over your operations, ensuring maximum efficiency.

Remote troubleshooting

IoT-enabled machines also simplify troubleshooting. When an issue arises, you no longer need to inspect the machine manually. Instead, the system diagnoses the problem and provides detailed insights. You can access this information remotely, saving time and effort.

For instance, if a component malfunctions, the machine sends an alert with the exact issue. You can then guide technicians or even resolve the problem yourself using remote tools. This reduces downtime and keeps production on track. Remote troubleshooting also minimizes repair costs by addressing issues early. With IoT, you can maintain seamless operations and avoid costly delays.

Modular and Flexible Designs

Configurations for diverse needs

Modern lighter making machines now feature modular designs that cater to a wide range of production requirements. You can configure these machines to handle different lighter styles, sizes, and materials without needing extensive retooling. This flexibility allows you to adapt quickly to changing market demands or customer preferences.

For example, modular systems let you swap out specific components, such as molds or assembly units, to produce unique designs. If you need to manufacture lighters with intricate patterns or custom branding, you can easily adjust the machine’s setup. This capability ensures you can meet diverse needs without investing in entirely new equipment.

Additionally, modular designs simplify scaling your operations. Whether you’re producing small batches or ramping up for mass production, you can modify the machine’s configuration to match your output goals. This adaptability makes modular systems a cost-effective solution for businesses of all sizes.

Simplified upgrades

Upgrading your lighter making machine has never been easier, thanks to modular and flexible designs. Instead of replacing the entire machine, you can now upgrade individual modules to enhance performance or add new features. This approach saves you time and reduces costs.

For instance, if a new technology improves energy efficiency or precision, you can integrate it into your existing machine by replacing only the relevant module. This ensures your equipment stays up-to-date without disrupting your production schedule. You also avoid the downtime associated with installing entirely new systems.

Simplified upgrades extend the lifespan of your equipment. By keeping your machines current, you maintain a competitive edge in the industry. Modular designs make it easier to adopt innovations, ensuring your production processes remain efficient and future-ready.

Advanced Safety Features

Automated safety protocols

Modern lighter making machines now come equipped with automated safety protocols to protect both the equipment and the production process. These protocols use advanced sensors and software to detect potential hazards in real time. For example, if a machine detects overheating or unusual vibrations, it automatically shuts down to prevent damage. This proactive approach ensures that you avoid costly repairs and production delays.

Automated safety systems also monitor the alignment and functionality of components during operation. If a part malfunctions or moves out of place, the system halts production and alerts you immediately. This reduces the risk of defective products reaching the market. By relying on these protocols, you can maintain consistent quality while safeguarding your equipment.

Another benefit of automation is its ability to enforce compliance with safety standards. Machines can be programmed to follow strict guidelines, ensuring every step of the process meets regulatory requirements. This reduces the burden on operators and minimizes human error.

Worker safety enhancements

Protecting workers is a top priority in any manufacturing environment. Lighter making machines now include features designed to enhance worker safety. For instance, many machines have built-in barriers or enclosures to prevent accidental contact with moving parts. These physical safeguards reduce the risk of injuries during operation.

Ergonomic designs also play a key role in worker safety. Machines are now easier to operate, with controls placed in accessible locations. This reduces strain and fatigue, allowing workers to perform their tasks more comfortably. Additionally, emergency stop buttons are strategically placed, enabling quick responses in case of an accident.

Training tools integrated into the machines further improve safety. Interactive displays guide workers through safe operating procedures, ensuring they understand how to handle the equipment properly. By prioritizing worker safety, you create a more secure and productive workplace.

Customization for Small-Batch Production

Personalized designs

Small-batch production has opened the door to creating unique and personalized designs. With modern lighter making machines, you can now cater to specific customer preferences. These machines allow you to produce lighters with intricate patterns, custom shapes, or even engraved messages. This level of personalization helps you meet the growing demand for products that reflect individuality.

For example, you can create limited-edition lighters for special events or holidays. Customers appreciate items that feel exclusive and tailored to their needs. By offering personalized designs, you can attract niche markets and build stronger customer loyalty. The ability to customize also gives you a competitive edge in a crowded marketplace.

Advanced software integrated into these machines makes the design process simple. You can upload digital designs directly to the machine, which then translates them into precise manufacturing instructions. This ensures accuracy and consistency, even for the most detailed features. Personalized designs not only enhance your product offerings but also elevate your brand’s reputation.

Branding integration

Branding plays a crucial role in small-batch production. Modern lighter making machines enable you to seamlessly integrate branding elements into your products. Whether it’s a company logo, slogan, or unique color scheme, you can incorporate these features directly into the manufacturing process.

This capability is especially valuable for businesses looking to promote their brand. For instance, you can produce custom-branded lighters for corporate giveaways or promotional events. These items serve as effective marketing tools, helping you increase brand visibility and recognition. Customers are more likely to remember your brand when it’s associated with a high-quality, customized product.

The precision of these machines ensures that branding elements are clear and professional. You can experiment with different materials, finishes, and printing techniques to achieve the desired look. By integrating branding into your products, you create a lasting impression and strengthen your market presence.

Cost-Effective Innovations

Reduced production costs

Modern lighter making machines now focus on reducing production costs without compromising quality. These machines incorporate advanced technologies that optimize resource usage. For example, energy-efficient motors and precision tools minimize material waste. You can save money by using fewer raw materials while maintaining high production standards.

Automation also plays a key role in cost reduction. Automated systems streamline operations, reducing the need for manual labor. This lowers labor costs and speeds up production. Additionally, predictive maintenance features prevent costly breakdowns. By addressing issues early, you avoid expensive repairs and downtime.

Another way to cut costs is through modular designs. Instead of replacing entire machines, you can upgrade specific components. This approach reduces capital expenses and extends the lifespan of your equipment. Investing in cost-effective innovations ensures your business remains profitable in a competitive market.

Tip: Track your production metrics regularly. Identifying inefficiencies early can help you save even more on operational costs.

Scalable solutions

Scalability is essential for adapting to market demands. Modern lighter making machines offer flexible configurations that grow with your business. You can start with a basic setup and expand as your production needs increase. This eliminates the need for costly new equipment when scaling up.

For instance, modular systems allow you to add new features or capabilities over time. If you need to produce more units or diversify your product line, you can easily adjust the machine’s configuration. This flexibility ensures you meet customer demands without overspending.

Scalable solutions also support small-batch production. You can switch between large-scale manufacturing and limited runs with minimal effort. This adaptability helps you respond quickly to market trends, keeping your business competitive.

Note: Investing in scalable machines today prepares you for future growth. It’s a smart way to stay ahead in the industry.

Global Standards and Compliance

Meeting international quality standards

Adhering to international quality standards ensures your lighter making machines meet global expectations. These standards, such as ISO 9001 or CE certification, guarantee that your products maintain consistent quality and safety. By following these guidelines, you build trust with customers and partners worldwide.

You can achieve compliance by integrating advanced quality control systems into your manufacturing process. Automated inspections and testing tools help you identify defects early. This ensures every lighter meets the required specifications before it leaves the production line. Consistency in quality not only satisfies regulatory requirements but also enhances your brand’s reputation.

Staying updated on evolving standards is essential. Regulatory bodies often revise guidelines to address new technologies or environmental concerns. You should regularly review these changes and adjust your processes accordingly. This proactive approach keeps your business competitive and compliant in a global market.

Tip: Partner with certification agencies to streamline the compliance process. Their expertise can help you navigate complex regulations efficiently.

Simplified global market entry

Meeting global standards simplifies your entry into international markets. When your machines comply with widely recognized certifications, you eliminate many barriers to trade. Importers and distributors prefer working with manufacturers who meet these requirements, as it reduces their risks.

Standardized compliance also speeds up the approval process in foreign markets. For example, if your machines already meet EU standards, you can quickly expand into European countries. This saves you time and resources, allowing you to focus on growing your business.

Additionally, compliance demonstrates your commitment to quality and safety. This builds confidence among potential buyers and partners. By aligning your products with global standards, you position your business as a reliable and professional player in the industry.

Note: Research the specific requirements of your target markets. Understanding local regulations ensures a smoother expansion process.

The top 10 trends in lighter making machines redefine efficiency, sustainability, and precision. Adopting these innovations keeps you competitive and future-ready. Embrace these advancements to meet evolving market demands. The future promises even smarter, greener, and more adaptable machines, ensuring your success in a rapidly changing industry. Stay ahead by innovating today.

FAQ

What are the benefits of using modular lighter making machines?

Modular machines let you upgrade parts instead of replacing the entire system. This saves money, reduces downtime, and keeps your equipment up-to-date with the latest technology.

How does IoT improve lighter production?

IoT enables real-time monitoring and remote troubleshooting. You can track performance, identify issues early, and optimize production processes for maximum efficiency and minimal waste.

Why is sustainability important in lighter manufacturing?

Sustainability reduces environmental impact and aligns with consumer expectations. Using eco-friendly materials and renewable energy improves your brand image and supports global environmental goals.

Tip: Start small by integrating one sustainable practice into your production process today.