Choosing the right printing machine for lighter production can make or break your business. It affects the quality of your designs, your production speed, and even your costs. You need to understand how different technologies work. This knowledge helps you pick a machine that meets your customization needs and boosts your efficiency.

Types of Printing Machines for Lighters

When it comes to printing on lighters, you’ve got several options. Each type of printing machine offers unique benefits, so understanding them helps you make the right choice for your needs.

Digital Printing Machines

Digital printing machines are perfect if you’re looking for flexibility. They let you print detailed designs directly onto lighters without needing plates or screens. This makes them ideal for small batches or custom orders. Plus, they handle full-color images with ease. If you want vibrant, high-resolution prints, digital printing is a great option. However, these machines can be a bit pricey upfront, so they’re best if you’re planning to produce high-value designs.

Screen Printing Machines

Screen printing machines are a classic choice. They’re known for their durability and ability to produce bold, solid colors. If you’re working with simple designs or logos, this method works like a charm. It’s also cost-effective for large production runs. However, screen printing requires more setup time since you’ll need to create screens for each design. This makes it less ideal for frequent design changes.

UV Printing Machines

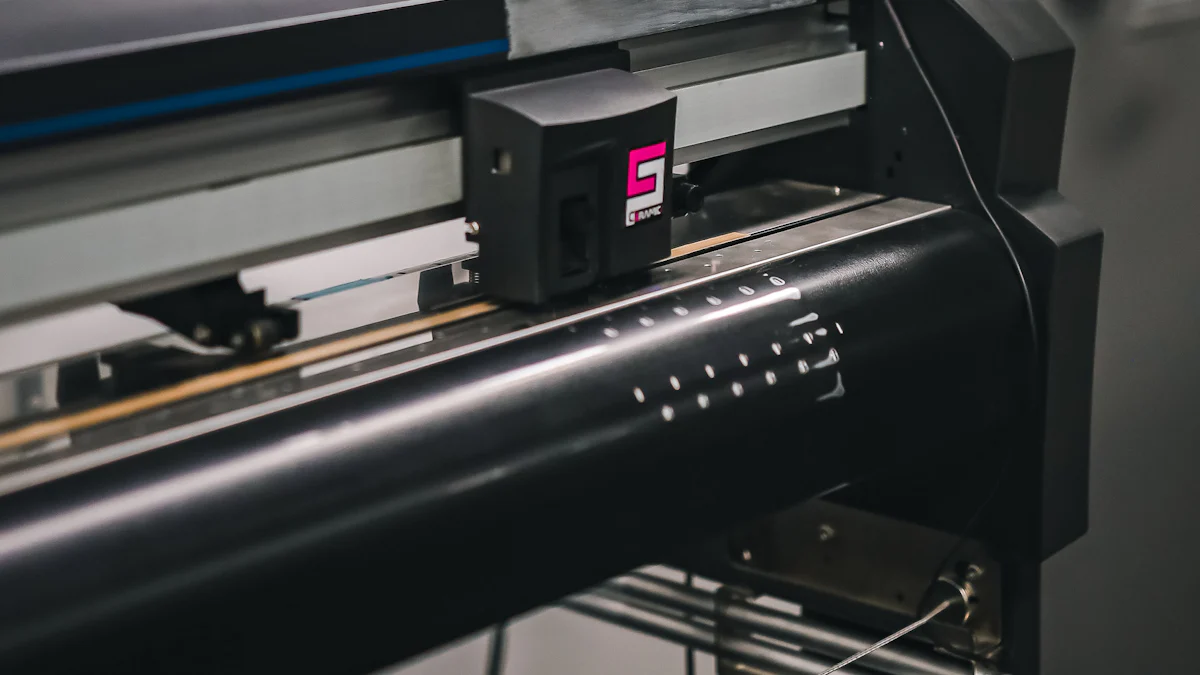

UV printing machines are all about speed and precision. They use ultraviolet light to cure the ink instantly, which means no drying time. This method works well for intricate designs and offers excellent adhesion to lighter surfaces. UV printing is also eco-friendly since it uses less ink and produces minimal waste. If you’re aiming for efficiency and sustainability, this might be your go-to option.

Pad Printing Machines

Pad printing machines are incredibly versatile. They use a silicone pad to transfer ink onto curved or uneven surfaces, making them perfect for lighters. This method is great for detailed designs and works well with a variety of materials. Pad printing is also relatively affordable, especially for medium to large production volumes. However, it may not be the best choice for full-color or highly complex images.

Tip: Think about your production goals and the type of designs you’ll be printing. This will help you decide which printing machine for lighter production suits you best.

Key Factors to Consider When Choosing a Printing Machine for Lighters

When you’re shopping for the perfect printing machine for lighter production, there are several factors you need to weigh. Let’s break them down so you can make the best choice.

Budget and Cost Efficiency

Your budget plays a big role in your decision. Some machines, like digital printers, have a higher upfront cost but offer flexibility and quality. Others, like screen printers, are more affordable but may require extra setup. Think about your long-term goals. Are you aiming for high-volume production or custom designs? Balancing cost with your needs will help you avoid overspending.

Printing Quality and Resolution

Do you want crisp, detailed designs or bold, solid colors? Different machines offer different levels of quality. Digital and UV printers excel at high-resolution images, while screen printing is great for simple, vibrant designs. Always test a sample print to see if the machine meets your expectations.

Speed and Production Volume

How fast do you need to produce lighters? If you’re handling large orders, speed is critical. UV printers are known for their quick turnaround, while pad printers are ideal for medium-scale production. Match the machine’s speed to your workload to keep up with demand.

Durability and Longevity

A good printing machine for lighter production should last for years. Look for machines made from durable materials and backed by solid warranties. Investing in a reliable machine saves you money on repairs and replacements.

Compatibility with Lighter Materials

Not all machines work with every type of lighter. Some printers handle plastic better, while others excel with metal. Check the machine’s specifications to ensure it’s compatible with the materials you use.

Space and Size Constraints

Printing machines come in all shapes and sizes. If your workspace is limited, look for compact models. Measure your available space before buying to avoid surprises.

Ease of Use and Maintenance

Nobody wants a machine that’s hard to operate. Choose one with user-friendly controls and clear instructions. Maintenance is also key. Machines that are easy to clean and calibrate will save you time and headaches.

Tip: Always consult the manufacturer or read reviews to understand how a machine performs in real-world settings.

Comparison of Printing Technologies for Lighters

When it comes to choosing the right printing technology, understanding the strengths of each option can make your decision much easier. Let’s dive into what makes each method stand out.

Advantages of Digital Printing

Digital printing offers unmatched flexibility. You can print intricate designs, gradients, and even photographs directly onto lighters. This method doesn’t require plates or screens, so it’s perfect for custom orders or small batches. Plus, digital printers handle full-color designs effortlessly. If you’re looking for vibrant, high-resolution prints, this is your best bet. However, keep in mind that digital printers often come with a higher price tag. They’re ideal if you’re focusing on premium designs or personalized products.

Benefits of Screen Printing

Screen printing is a tried-and-true method. It’s great for bold, solid colors and simple designs like logos or text. This technique shines in high-volume production since it’s cost-effective and produces consistent results. While it does require more setup time, the durability of the prints makes it worth the effort. If you’re working with straightforward designs and need to produce large quantities, screen printing is a reliable choice.

Why Choose UV Printing?

UV printing stands out for its speed and precision. The ink cures instantly under ultraviolet light, so there’s no waiting for it to dry. This makes it a fantastic option for fast production. UV printing also works well on various materials, including plastic and metal, and offers excellent adhesion. If sustainability matters to you, you’ll appreciate that this method uses less ink and generates minimal waste. It’s a win-win for efficiency and eco-friendliness.

Key Differences Between Printing Technologies

Here’s a quick comparison to help you decide:

| Feature | Digital Printing | Screen Printing | UV Printing |

|---|---|---|---|

| Best For | Custom, detailed designs | Simple, bold designs | Fast, high-precision work |

| Setup Time | Minimal | High | Minimal |

| Cost Efficiency | High for small batches | High for large volumes | Moderate |

| Material Compatibility | Limited to flat surfaces | Works on most surfaces | Works on various materials |

Tip: Think about your production goals and the type of designs you’ll create. Matching the right technology to your needs will save you time and money.

Maintenance and Operational Tips for Printing Machines

Keeping your printing machine in top shape doesn’t have to be complicated. A little care goes a long way in ensuring smooth operations and extending the life of your equipment. Here’s how you can do it.

Regular Cleaning and Calibration

Dust and ink residue can build up over time, affecting your machine’s performance. Clean your printer regularly to prevent clogs and smudges. Use a soft cloth and manufacturer-approved cleaning solutions. Don’t forget to calibrate the machine after cleaning. Calibration ensures accurate prints and keeps your designs looking sharp. Set a reminder to clean and calibrate weekly or after heavy use.

Pro Tip: Always turn off the machine before cleaning to avoid damaging sensitive parts.

Proper Handling of Printing Materials

Handle your printing materials with care. Store inks, pads, and screens in a cool, dry place to maintain their quality. Avoid touching the printing surfaces with bare hands, as oils from your skin can interfere with the process. When loading materials, double-check that they’re aligned correctly to prevent jams or misprints.

Troubleshooting Common Issues

Even the best machines can run into problems. If you notice streaks, uneven prints, or misalignments, check the ink levels and print heads first. Sometimes, a quick cleaning or resetting the machine solves the issue. For more complex problems, consult the user manual or contact customer support.

Note: Keep a troubleshooting guide handy. It can save you time when something goes wrong.

Scheduling Routine Maintenance

Routine maintenance is key to avoiding costly repairs. Schedule professional servicing at least once a year. Technicians can spot wear and tear that you might miss. Regular check-ups keep your machine running efficiently and help you avoid unexpected downtime.

Reminder: Log all maintenance activities. This helps you track when the next service is due.

By following these tips, you’ll keep your printing machine running like new and ensure consistent, high-quality results.

Choosing the right printing machine for lighters can transform your production process. Understanding the features of each machine helps you make smarter decisions. Always match the machine to your specific goals and needs.

Pro Tip: Talk to manufacturers or test machines before buying. This ensures you get the perfect fit for your business.