Essential Tips for Selecting a Lighter Making Machine

Choosing the right lighter making machine can make or break your business. This decision directly impacts your production efficiency, cost management, and overall growth. A well-suited machine doesn’t just streamline operations; it sets the foundation for long-term success. Whether you’re scaling up or starting fresh, understanding the lighter making machine introduction is essential. The right equipment ensures you meet demand, maintain quality, and stay competitive in the market. Don’t underestimate how much the right machine can transform your workflow and profitability.

Key Takeaways

- Assess your production volume to choose a machine that meets your output needs, preventing bottlenecks in your operations.

- Define the type of lighters you want to produce, as different machines cater to specific designs and materials, ensuring quality and reducing waste.

- Align your machine choice with your long-term business goals, such as sustainability or automation, to support future growth.

- Prioritize features like productivity, durability, and adaptability in a machine to enhance efficiency and accommodate changing business needs.

- Consider the financial implications of buying versus renting a machine, evaluating which option best suits your budget and operational plans.

- Ensure the machine fits your workspace by measuring available space and considering integration with existing equipment for a smooth workflow.

- Invest in strong customer support and maintenance plans to ensure your machine remains reliable and efficient, safeguarding your investment.

Identifying Your Business Needs

When selecting a lighter making machine, understanding your business needs is the first step. This ensures you invest in equipment that aligns with your goals and supports your operations effectively. Let’s break it down into three key areas to consider.

Assessing Production Volume

Start by evaluating how many lighters you plan to produce daily, weekly, or monthly. Your production volume determines the type of machine you need. If your business requires high output, look for machines designed for large-scale manufacturing. For smaller operations, a compact and efficient machine might be a better fit. Matching the machine’s capacity to your production goals prevents bottlenecks and ensures smooth operations.

Defining Product Type and Specifications

Think about the type of lighters you want to manufacture. Are you producing disposable lighters, refillable ones, or a specific design? Each type has unique requirements, and not all machines can handle every specification. Consider factors like size, material, and design features. Choosing a machine tailored to your product ensures consistent quality and reduces waste. This step is crucial in the lighter making machine introduction process, as it directly impacts your product’s market appeal.

Evaluating Business Goals

Your long-term business goals should guide your decision. Are you aiming to scale production, enter new markets, or improve efficiency? A machine that aligns with these objectives will support your growth. For instance, if sustainability is a priority, look for energy-efficient options. If you want to reduce labor costs, consider machines with automation features. Clear goals help you make a choice that benefits your business in the long run.

“The right machine doesn’t just meet your current needs; it sets the stage for future success.”

By identifying your business needs, you lay the foundation for a smart investment. This step ensures the machine you choose fits seamlessly into your operations and supports your vision.

Key Machine Features to Consider

When choosing a lighter making machine, focusing on the right features can save you time, money, and effort. The right machine doesn’t just meet your needs today; it grows with your business. Let’s explore the key features you should prioritize.

Productivity and Efficiency

A machine’s productivity directly impacts your output. You need equipment that can handle your production goals without delays. Look for machines with faster cycle times and minimal downtime. High-speed operations ensure you meet demand while maintaining quality. Efficient machines also reduce waste, which helps you save on material costs. By prioritizing productivity, you’ll keep your workflow smooth and your customers satisfied.

Durability and Build Quality

Durability matters when investing in machinery. A well-built machine lasts longer and performs consistently. Check the materials used in its construction. Machines made from high-quality metals or alloys resist wear and tear better. Reliable build quality reduces the risk of breakdowns, saving you from costly repairs. A durable machine ensures uninterrupted production, which is essential for meeting deadlines and maintaining customer trust.

Adaptability and Flexibility

Your business needs may change over time. A flexible machine adapts to new requirements without needing a complete replacement. Look for equipment that supports multiple lighter designs or materials. Machines with adjustable settings give you the freedom to experiment with new products. This adaptability keeps you competitive in a changing market. Investing in a versatile machine prepares your business for future opportunities.

“The right features in a lighter making machine can transform your operations and set you up for long-term success.”

By focusing on these features, you’ll make a smarter investment. A productive, durable, and adaptable machine ensures your business stays efficient and ready for growth.

Automation and Technology

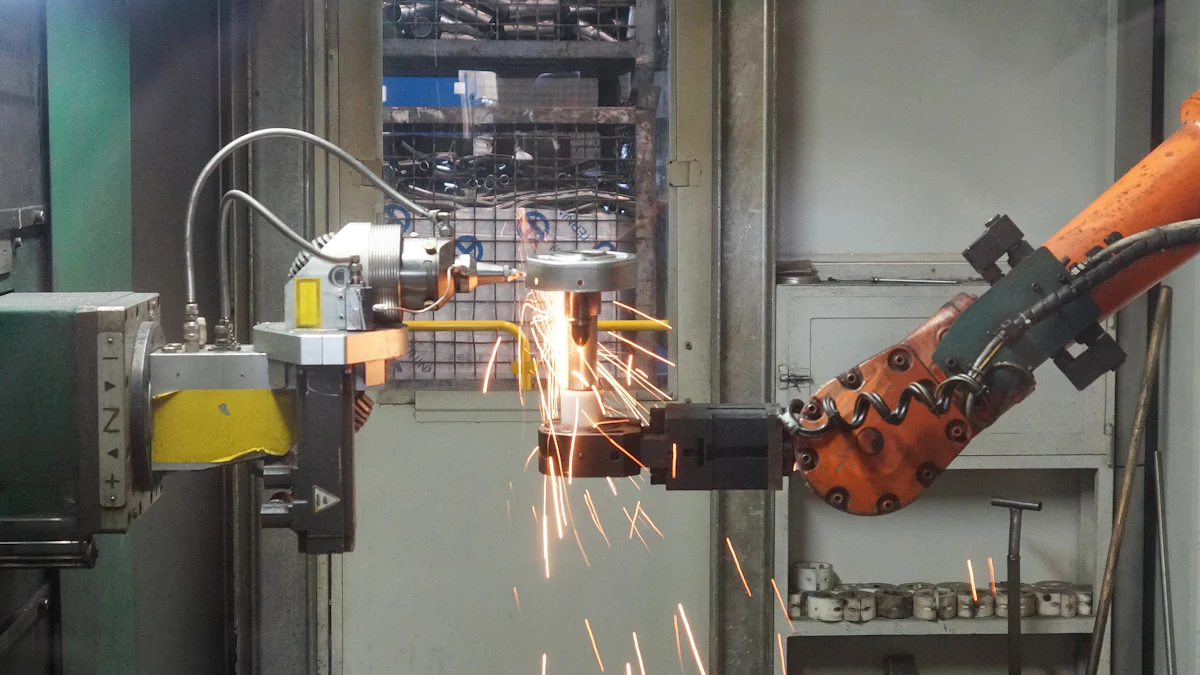

Automation plays a vital role in modern manufacturing. When selecting a lighter making machine, you should prioritize automation features that simplify operations and reduce manual intervention. Automated machines can handle repetitive tasks with precision, which minimizes errors and boosts productivity. Look for equipment with programmable settings. These allow you to customize production processes for different lighter designs without constant adjustments. Advanced automation also reduces the need for extensive training, making it easier for your team to operate the machine efficiently.

Technology integration is another key factor. Machines equipped with smart technology, such as sensors and monitoring systems, can provide real-time data on performance. This helps you identify issues early and maintain consistent quality. Some machines even offer remote access, enabling you to monitor and control operations from anywhere. By embracing automation and technology, you can streamline your workflow and stay ahead in a competitive market.

Safety and Compliance Features

Safety should always be a top priority when choosing a lighter making machine. Manufacturing involves risks, and the right safety features protect your team and ensure smooth operations. Look for machines with built-in safety mechanisms, such as emergency stop buttons and protective guards. These features prevent accidents and create a safer work environment.

Compliance with industry regulations is equally important. Machines that meet safety standards help you avoid legal issues and maintain your reputation. Check for certifications that confirm the machine adheres to required guidelines. Investing in safety and compliance features not only protects your workers but also builds trust with your customers. A safe and compliant machine reflects your commitment to quality and responsibility.

Energy Efficiency and Sustainability

Energy efficiency is a critical consideration for any business. Machines that consume less energy can significantly lower your operational costs. Look for equipment designed with energy-saving features, such as optimized power usage or standby modes. These features reduce electricity consumption without compromising performance. An energy-efficient machine helps you save money while supporting your sustainability goals.

Sustainability goes beyond energy use. Consider machines that minimize waste during production. Some models are designed to use materials more efficiently, reducing scrap and improving overall output. Choosing a sustainable machine aligns your business with eco-friendly practices, which can enhance your brand image. Customers increasingly value companies that prioritize environmental responsibility. By focusing on energy efficiency and sustainability, you contribute to a greener future while improving your bottom line.

Cost and Investment Considerations

When investing in a lighter making machine, understanding the financial aspects is just as important as evaluating its features. Making the right financial decision ensures your business remains profitable and sustainable. Let’s dive into the key considerations.

Buying vs Renting

One of the first decisions you’ll face is whether to buy or rent the machine. Each option has its own advantages, depending on your business situation. Buying gives you full ownership. This means you can use the machine without restrictions and customize it to fit your needs. It’s a long-term investment that can save you money over time, especially if you plan to use the machine for years.

Renting, on the other hand, offers flexibility. If you’re just starting out or testing the market, renting might be the better choice. It requires less upfront capital, which reduces financial risk. Renting also allows you to upgrade to newer models without worrying about selling old equipment. However, rental costs can add up over time, so it’s essential to calculate whether this option makes sense for your budget.

Calculating Long-Term ROI

Return on investment (ROI) is a critical factor when choosing a lighter making machine. You need to consider how quickly the machine will pay for itself through increased productivity and reduced costs. Start by estimating your production output and the revenue it will generate. Compare this to the machine’s cost, including maintenance and operational expenses.

A high-quality machine may have a higher upfront cost, but it often delivers better ROI. Durable machines require fewer repairs, saving you money in the long run. Automated features can reduce labor costs and improve efficiency, further boosting your returns. By focusing on long-term ROI, you ensure your investment contributes to your business’s growth and profitability.

Budgeting for Additional Costs

The price tag of the machine isn’t the only expense you’ll face. Additional costs can quickly add up, so it’s important to plan for them. Maintenance and repair expenses are inevitable, even with the most reliable machines. Regular servicing keeps the machine running smoothly and prevents costly breakdowns.

You’ll also need to consider installation costs. Some machines require professional setup, which can be an added expense. Training your team to operate the machine is another factor. While automated machines are easier to use, initial training ensures your staff can maximize the equipment’s potential.

Finally, don’t forget about energy costs. Machines with high energy consumption can increase your utility bills. Opting for energy-efficient models helps you save money while supporting sustainability efforts. By accounting for these additional costs, you avoid surprises and maintain control over your budget.

“A well-planned investment in a lighter making machine sets the foundation for financial stability and business success.”

Understanding these cost considerations helps you make an informed decision. Whether you choose to buy or rent, focus on long-term ROI and prepare for extra expenses. This approach ensures your investment aligns with your business goals and keeps your operations running smoothly.

Space and Workflow Integration

When selecting a lighter making machine, you need to think about how it fits into your workspace and overall operations. A well-integrated machine ensures smooth workflows and maximizes efficiency. Let’s dive into two critical aspects of this process.

Machine Size and Space Requirements

The size of the machine plays a huge role in determining whether it will fit into your existing workspace. Before making a purchase, measure the available space in your facility. Consider not just the machine’s footprint but also the room needed for operators to move around it comfortably. Crowded workspaces can lead to inefficiencies and safety hazards.

Compact machines are ideal for businesses with limited space. They save room while still delivering solid performance. Larger machines, on the other hand, might require you to rearrange your layout or even expand your facility. Think about your long-term plans. If you expect to scale production, choosing a machine that fits your future needs is a smart move.

“A machine that fits your space perfectly creates a safer and more efficient work environment.”

Compatibility with Existing Setup

Your new machine should integrate seamlessly with your current workflow. Evaluate how it will connect with other equipment in your production line. For example, does it align with your material handling systems? Will it require additional tools or modifications to function properly? These questions help you avoid disruptions during installation.

Also, consider the power requirements of the machine. Ensure your facility can support its energy needs without overloading your system. Machines with advanced automation features might need software integration. Check if your existing technology can handle this or if upgrades are necessary. A compatible machine keeps your operations running smoothly and minimizes downtime.

By focusing on space and workflow integration, you ensure the machine enhances your production process instead of complicating it. This step helps you create a workspace that supports efficiency and growth.

Customer Support and Maintenance

When investing in a lighter making machine, customer support and maintenance play a vital role in ensuring smooth operations. Reliable support can save you time, money, and stress when challenges arise. Let’s explore the key aspects to consider.

After-Sales Service and Support

After-sales service is a critical factor when choosing a machine. You need a manufacturer or supplier who stands by their product and offers prompt assistance. Check if they provide technical support for troubleshooting issues. A responsive support team can help you resolve problems quickly, minimizing downtime and keeping your production on track.

Some companies offer training sessions to help your team understand the machine better. This can be especially useful if the equipment includes advanced features or automation. Ask about the availability of spare parts. A supplier with a well-stocked inventory ensures you won’t face delays when replacements are needed. Reliable after-sales service gives you peace of mind and helps you maintain consistent production quality.

Warranties and Maintenance Plans

A warranty is more than just a safety net; it’s a sign of the manufacturer’s confidence in their product. Look for machines that come with comprehensive warranties covering major components and potential defects. A longer warranty period often indicates higher reliability and durability. Make sure you understand the terms and conditions, so you know what’s covered and what isn’t.

Maintenance plans are equally important. Regular maintenance keeps your machine running efficiently and extends its lifespan. Some suppliers offer maintenance packages that include scheduled servicing and inspections. These plans can save you from unexpected repair costs and ensure your machine operates at peak performance. Investing in a good maintenance plan protects your investment and reduces the risk of costly breakdowns.

“Strong customer support and a solid maintenance plan are the backbone of a successful manufacturing operation.”

By prioritizing after-sales service, warranties, and maintenance plans, you set your business up for long-term success. These factors ensure your lighter making machine remains reliable and efficient, supporting your growth and profitability.

Selecting the right lighter making machine is a decision that shapes your business’s future. You’ve learned how to assess your needs, evaluate machine features, and consider costs. You’ve also explored the importance of space planning and reliable support. Now, it’s time to apply this knowledge. Choose a machine that aligns with your goals and enhances your operations. A reliable and efficient machine isn’t just an expense—it’s an investment in your success. Take the next step confidently, knowing you’re equipped to make the best choice for your business.

FAQ

What factors should I prioritize when choosing a lighter making machine?

You should focus on your production needs, machine features, and budget. Consider the type of lighters you plan to produce, the machine’s capacity, and its compatibility with your workspace. Features like automation, energy efficiency, and safety should also be high on your list.

How do I determine the right production capacity for my business?

Start by analyzing your current and projected demand. Estimate how many lighters you need to produce daily or monthly. Choose a machine that matches or slightly exceeds this capacity to ensure smooth operations and room for growth.

Are automated machines worth the investment?

Yes, automated machines can save you time and reduce labor costs. They improve efficiency by handling repetitive tasks with precision. Automation also minimizes errors and ensures consistent product quality, making it a valuable long-term investment.

What safety features should I look for in a lighter making machine?

Look for emergency stop buttons, protective guards, and compliance with industry safety standards. Machines with built-in safety mechanisms reduce risks and create a safer work environment for your team.

Should I buy or rent a lighter making machine?

This depends on your business needs and financial situation. Buying is ideal for long-term use and customization. Renting works well if you’re testing the market or have limited capital. Evaluate the costs and benefits of each option before deciding.

How can I ensure the machine fits into my existing workspace?

Measure your available space and compare it to the machine’s dimensions. Consider the room needed for operators and maintenance access. Compact machines work well in smaller spaces, while larger ones may require layout adjustments.

What maintenance requirements should I expect?

Regular maintenance includes cleaning, lubrication, and part replacements. Some manufacturers offer maintenance plans that cover inspections and servicing. Following the recommended schedule keeps your machine running efficiently and extends its lifespan.

How do I calculate the ROI of a lighter making machine?

Estimate your production output and the revenue it will generate. Subtract the machine’s cost, including maintenance and operational expenses. A high-quality machine with advanced features often delivers better ROI through increased productivity and reduced costs.

What role does energy efficiency play in machine selection?

Energy-efficient machines lower your operational costs and support sustainability goals. Look for features like optimized power usage or standby modes. These not only save money but also align your business with eco-friendly practices.

How important is after-sales support?

After-sales support is crucial for resolving issues quickly and minimizing downtime. Choose a supplier that offers technical assistance, training, and easy access to spare parts. Reliable support ensures your machine operates smoothly and consistently.