Flame quality plays a crucial role in lighter manufacturing. Variations in flame size, ignition, and stability can compromise both performance and safety. The Fully Automatic Lighter Test Machine offers a groundbreaking solution to these challenges. It automates the testing process, ensuring precise detection of flame inconsistencies. By identifying and addressing anomalies, this machine guarantees consistent flame performance. Manufacturers can rely on it to enhance product reliability and meet high-quality standards. This innovation not only improves safety but also elevates the overall user experience.

Key Takeaways

- Fully Automatic Lighter Test Machines automate the testing process, ensuring precise detection of flame inconsistencies, which enhances product reliability.

- By addressing common flame quality issues like uneven flame size, ignition failures, and instability, these machines significantly improve safety and user experience.

- The machines feature advanced sensors that provide accurate measurements, allowing manufacturers to maintain consistent flame size and performance.

- Integrating these machines into production lines streamlines operations, reduces manual inspections, and increases overall efficiency.

- Investing in a Fully Automatic Lighter Test Machine helps manufacturers comply with safety and quality standards, building trust with consumers.

- High-speed testing capabilities allow for processing multiple lighters quickly, helping manufacturers meet production targets without sacrificing quality.

- Overall, these machines not only enhance product quality but also strengthen a brand’s reputation in the competitive lighter market.

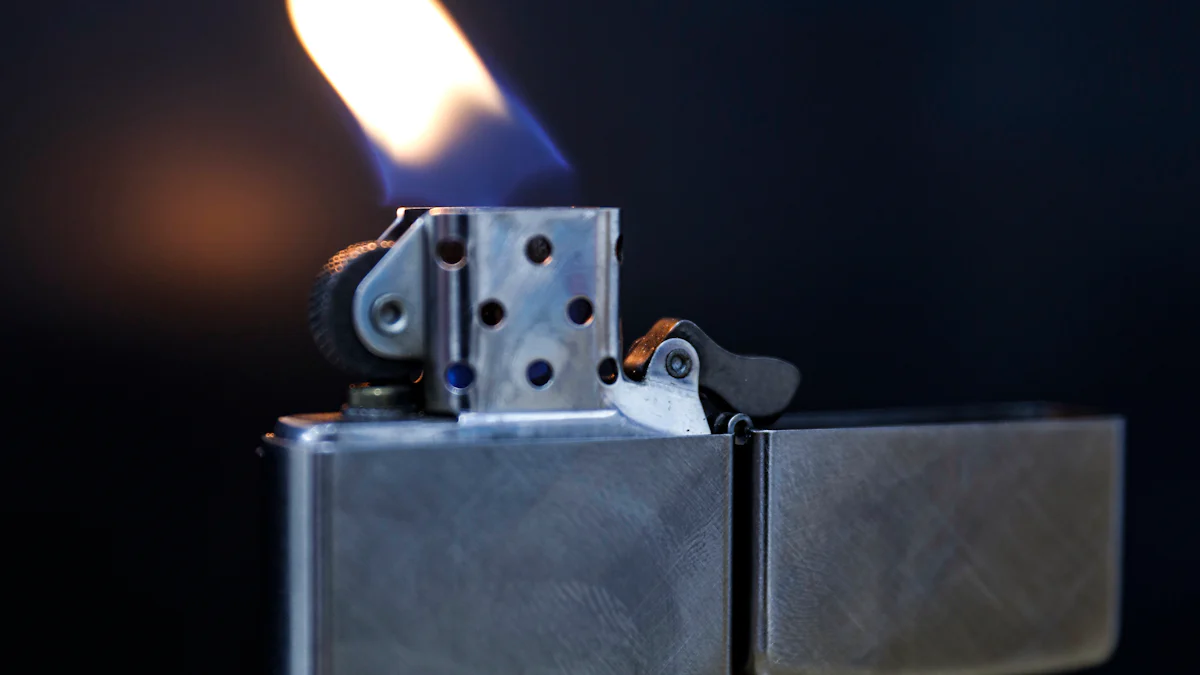

Common Flame Quality Issues in Lighters

Lighters are essential tools in daily life, but their performance can be compromised by common flame quality issues. These problems not only affect functionality but also pose safety risks. Understanding these issues helps you recognize the importance of advanced testing solutions.

Uneven Flame Size

Uneven flame size is a frequent problem in lighters. You may notice that the flame fluctuates or appears irregular during use. This inconsistency often results from variations in the assembly process or defects in components. Uneven flames can make it difficult to control the lighter, reducing its reliability. Addressing this issue requires precise detection and correction during manufacturing.

Ignition Failures

Ignition failures occur when a lighter struggles to produce a flame. You might experience this as repeated attempts to ignite the lighter without success. These failures often stem from faulty ignition systems or improper fuel flow. Such issues can frustrate users and diminish trust in the product. Manufacturers must ensure that every lighter ignites reliably to meet user expectations.

Inconsistent Flame Stability

Flame stability is crucial for safe and effective lighter operation. An unstable flame may flicker, waver, or extinguish unexpectedly. This instability can result from poor fuel regulation or inadequate testing during production. Unstable flames not only hinder usability but also increase the risk of accidents. Ensuring stable flames requires thorough quality control measures.

Fully Automatic Lighter Test Machine: An Overview

What Is a Fully Automatic Lighter Test Machine?

A Fully Automatic Lighter Test Machine is an advanced tool designed to ensure the quality and reliability of lighters during production. It automates the process of inspecting flame characteristics, such as size, stability, and ignition. Unlike manual testing methods, this machine uses precise technology to detect inconsistencies that may arise from assembly or component variations. By integrating this machine into your production line, you can achieve consistent results and maintain high-quality standards.

This machine eliminates the need for manual inspections, which can be time-consuming and prone to human error. It operates with remarkable accuracy, ensuring that every lighter meets strict performance and safety requirements. Whether you manufacture lighters on a small or large scale, this machine provides a reliable solution for quality control.

Key Features and Functionality

The Fully Automatic Lighter Test Machine comes equipped with several features that make it indispensable for lighter manufacturing. These features are designed to streamline operations and enhance product quality.

- Automated Flame Detection: The machine evaluates flame size, stability, and ignition with precision. It identifies even the slightest anomalies, ensuring that defective products are flagged for correction.

- High-Speed Testing: It processes multiple lighters in a short time, increasing efficiency without compromising accuracy.

- User-Friendly Interface: The machine’s interface allows you to adjust settings easily and monitor performance in real-time.

- Durable Design: Built for long-term use, the machine withstands the demands of high-volume production environments.

- Safety Mechanisms: It includes built-in safety features to protect operators and maintain a secure working environment.

These functionalities make the machine a valuable asset for improving both operational efficiency and product reliability.

Integration with Manufacturing Processes

Incorporating the Fully Automatic Lighter Test Machine into your production line is straightforward. Its design ensures compatibility with existing manufacturing setups, minimizing disruptions during installation. Once integrated, the machine works seamlessly alongside other equipment, such as assembly and packaging machines.

The machine’s automated nature reduces the need for manual intervention, allowing your team to focus on other critical tasks. It also enhances workflow by identifying defective products early in the process, preventing delays and reducing waste. By using this machine, you can optimize your production line and ensure that every lighter meets the highest standards of quality and safety.

Investing in this machine not only improves your manufacturing process but also strengthens your brand’s reputation for delivering reliable and safe products.

How Fully Automatic Lighter Test Machines Address Flame Quality Issues

Precision in Flame Size Detection

Flame size plays a critical role in the performance of a lighter. Variations in size can lead to inconsistent functionality and user dissatisfaction. The Fully Automatic Lighter Test Machine ensures precise flame size detection by using advanced sensors and technology. These sensors measure the flame with exceptional accuracy, identifying even the smallest deviations. You can rely on this machine to detect irregularities that may result from assembly errors or component inconsistencies.

This precision allows manufacturers to address issues before the product reaches consumers. By maintaining uniform flame size, you enhance the reliability of your lighters. Consistent flame size not only improves usability but also ensures safety during operation. With this machine, you gain the ability to deliver products that meet high-quality standards every time.

Reliable Ignition Testing

Ignition reliability is essential for any lighter. A lighter that fails to ignite consistently can frustrate users and harm your brand’s reputation. The Fully Automatic Lighter Test Machine performs reliable ignition testing to ensure every lighter functions as expected. It simulates real-world usage conditions to evaluate the ignition system’s performance.

This machine identifies problems such as faulty ignition mechanisms or improper fuel flow. By detecting these issues early, you can prevent defective products from reaching the market. Reliable ignition testing helps you build trust with your customers. When users experience dependable performance, they are more likely to choose your brand again.

Ensuring Flame Stability

Flame stability is a key factor in lighter safety and functionality. An unstable flame can flicker, waver, or extinguish unexpectedly, posing risks to users. The Fully Automatic Lighter Test Machine ensures flame stability by analyzing the flame’s behavior under various conditions. It evaluates factors like fuel regulation and airflow to detect potential instability.

By addressing flame stability issues during production, you reduce the likelihood of accidents and improve user satisfaction. Stable flames make lighters easier and safer to use. This machine provides you with the tools to guarantee that every lighter meets strict safety and performance criteria. With its help, you can confidently deliver products that align with consumer expectations.

The Fully Automatic Lighter Test Machine offers a comprehensive solution to flame quality issues. Its ability to detect flame size variations, test ignition reliability, and ensure flame stability makes it an indispensable tool for manufacturers. By integrating this machine into your production process, you can achieve consistent quality and enhance customer trust.

Benefits of Using Fully Automatic Lighter Test Machines

Enhanced Product Quality

You can achieve superior product quality by incorporating advanced testing solutions into your manufacturing process. The Fully Automatic Lighter Test Machine ensures that every lighter meets strict performance standards. It detects even the smallest inconsistencies in flame size, ignition, and stability. This precision minimizes defects and guarantees that only reliable products reach your customers. High-quality lighters not only enhance user satisfaction but also strengthen your brand’s reputation in the market.

Increased Operational Efficiency

Streamlining your production line becomes easier with automated testing. The Fully Automatic Lighter Test Machine reduces the need for manual inspections, saving time and labor costs. Its high-speed testing capabilities allow you to process multiple lighters in a short period. This efficiency helps you meet production targets without compromising on quality. By optimizing your workflow, you can allocate resources more effectively and focus on other critical aspects of manufacturing.

Compliance with Safety and Quality Standards

Meeting safety and quality standards is essential in lighter manufacturing. The Fully Automatic Lighter Test Machine helps you adhere to these requirements by ensuring consistent product performance. It identifies potential safety risks, such as unstable flames or ignition failures, during the testing phase. This proactive approach reduces the likelihood of recalls or customer complaints. Compliance with industry standards not only protects your business but also builds trust with your consumers.

Investing in this machine provides you with a competitive edge. It enhances product quality, boosts operational efficiency, and ensures compliance with safety regulations. These benefits make it an indispensable tool for any lighter manufacturing operation.

Fully Automatic Lighter Test Machines transform your manufacturing process. These machines ensure consistent flame quality by automating testing and eliminating errors. You can enhance safety, improve product reliability, and streamline workflows with their advanced features. By investing in this technology, you position your business to meet high-quality standards and exceed consumer expectations. This strategic move not only boosts operational efficiency but also strengthens your brand’s reputation in the competitive market.

FAQ

What is the primary purpose of a Fully Automatic Lighter Test Machine?

The primary purpose of this machine is to ensure the quality and reliability of lighters during production. It automates the testing process, detecting inconsistencies in flame size, ignition, and stability. This ensures that every lighter meets strict performance and safety standards.

How does the machine improve flame quality?

The machine uses advanced sensors and technology to analyze flame characteristics with precision. It detects irregularities in flame size, ignition, and stability. By addressing these issues during production, it guarantees consistent flame quality for every lighter.

Can the machine handle high-volume production?

Yes, the machine is designed for high-speed testing. It processes multiple lighters in a short time without compromising accuracy. This makes it ideal for manufacturers handling large-scale production.

Is the machine easy to integrate into existing production lines?

Yes, the machine is built for seamless integration. Its design ensures compatibility with most manufacturing setups. You can incorporate it into your production line with minimal disruption.

Does the machine require specialized training to operate?

No, the machine features a user-friendly interface. You can easily adjust settings and monitor performance in real-time. Basic training is sufficient for operators to use it effectively.

What safety features does the machine include?

The machine includes built-in safety mechanisms to protect operators. These features ensure a secure working environment while maintaining high-quality testing standards.

How does the machine reduce production costs?

The machine automates the testing process, reducing the need for manual inspections. This saves time and labor costs. Its high-speed capabilities also help you meet production targets efficiently.

Can the machine help with compliance to safety standards?

Yes, the machine ensures that every lighter meets industry safety and quality standards. It identifies potential risks, such as unstable flames or ignition failures, during the testing phase. This helps you avoid recalls and maintain compliance.

What types of lighters can the machine test?

The machine is versatile and can test various types of lighters. Whether you produce disposable, refillable, or specialty lighters, the machine ensures consistent quality across all products.

Why should I invest in a Fully Automatic Lighter Test Machine?

Investing in this machine enhances product quality, boosts operational efficiency, and ensures compliance with safety regulations. It strengthens your brand’s reputation and gives you a competitive edge in the market.