Choosing the right lighter making machine can transform your production process. It ensures efficiency, cost savings, and consistent quality. In 2025, advancements like the adjust flame machine have redefined manufacturing standards. Staying informed about these innovations helps you make smarter investments and stay competitive in a rapidly evolving industry.

Key Takeaways

- Picking the right lighter machine helps work faster and cheaper. Choose machines that fit your production needs best.

- Being eco-friendly is important in 2025. Find machines that use green materials and create less waste to attract eco-friendly buyers.

- Automation makes work faster and better. Get machines with smart automation to simplify tasks and reduce handwork.

Overview of the Lighter-Making Industry in 2025

Key Trends in Lighter Manufacturing

In 2025, the lighter manufacturing industry has embraced sustainability and innovation. You’ll notice a growing shift toward eco-friendly materials like biodegradable plastics and recycled metals. Manufacturers now prioritize reducing waste and energy consumption during production. Customization has also become a key trend. Many companies offer personalized designs to meet consumer preferences. Additionally, the demand for refillable lighters has surged, as more people seek reusable options to minimize environmental impact.

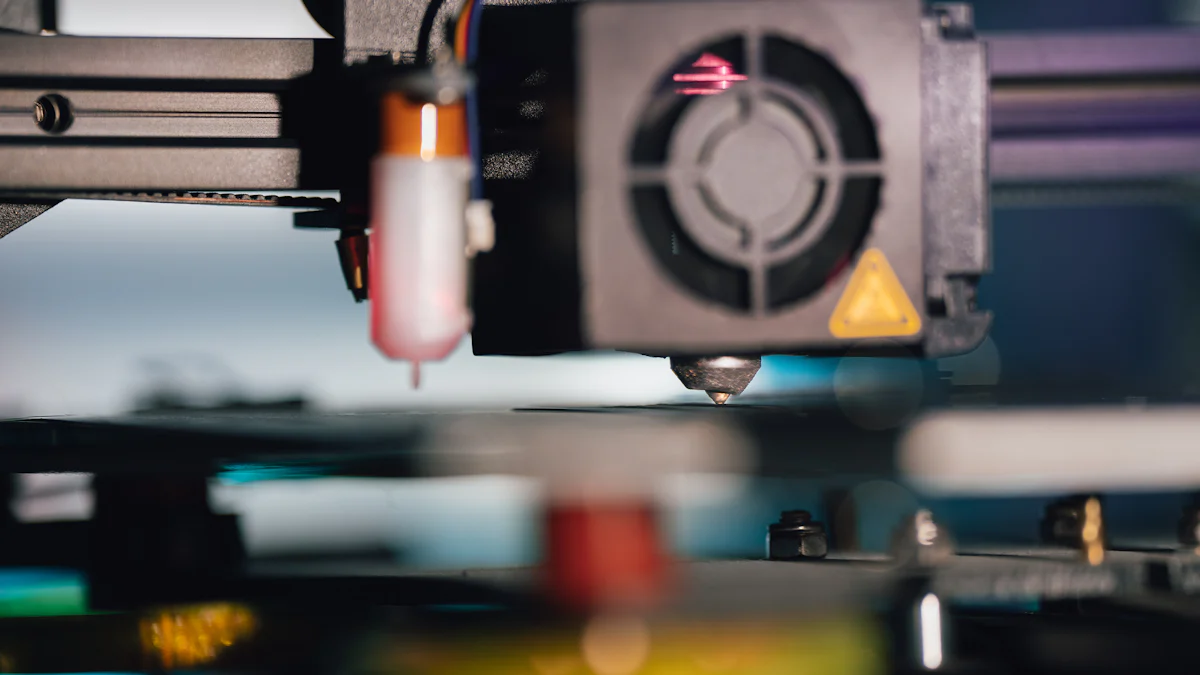

Advancements in Lighter-Making Technology

Technology has revolutionized how lighter making machines operate. Modern machines now feature advanced automation, allowing you to streamline production with minimal manual intervention. Smart sensors and AI integration ensure precision and reduce errors. Some machines even include real-time monitoring systems, so you can track performance and identify issues instantly. These advancements not only improve efficiency but also enhance the quality of the final product. Compact and modular designs have also made it easier to adapt machines to different production scales.

Market Demand and Industry Growth

The global demand for lighters continues to grow, driven by both traditional and niche markets. You’ll find that outdoor enthusiasts, smokers, and even collectors contribute to this demand. Emerging markets in Asia and Africa have seen significant growth, creating new opportunities for manufacturers. The industry’s focus on innovation and sustainability has also attracted environmentally conscious consumers. As a result, lighter making machines have become essential for businesses looking to capitalize on this expanding market.

Key Features to Consider When Choosing a Lighter-Making Machine

Build Quality and Durability

When selecting a lighter making machine, you need to evaluate its build quality. Machines made from high-grade materials last longer and perform better under heavy use. Look for corrosion-resistant components, especially if your production environment involves exposure to moisture or chemicals. Durable machines reduce downtime and maintenance costs, ensuring smooth operations over time.

Automation and Ease of Use

Automation plays a crucial role in modern manufacturing. A machine with advanced automation features simplifies your workflow and minimizes manual labor. User-friendly interfaces, such as touchscreens or intuitive controls, make operation easier for your team. Machines with pre-programmed settings save time and reduce errors, especially during large-scale production.

Production Speed and Efficiency

Production speed directly impacts your output and profitability. Choose a machine that matches your production goals without compromising quality. High-speed machines with efficient mechanisms help you meet tight deadlines and handle bulk orders. Efficiency also reduces energy consumption, which lowers operational costs.

Cost-Effectiveness and ROI

Investing in a lighter making machine requires careful cost analysis. Consider the initial price, maintenance expenses, and long-term savings. Machines with energy-efficient designs and low maintenance needs offer better returns on investment. Evaluate how quickly the machine can pay for itself through increased productivity and reduced waste.

Safety Features and Compliance

Safety should always be a priority. Machines with built-in safety features, such as emergency stop buttons and protective shields, prevent accidents. Ensure the machine complies with industry standards and local regulations. Compliance not only protects your workers but also avoids legal issues and fines.

Comparison of the Top Lighter-Making Machines in 2025

Machine 1: Societe BIC SA Automatic Lighter Maker

This machine stands out for its reliability and precision. It features a robust design, ensuring long-term durability. You can benefit from its advanced automation, which reduces manual intervention. The machine excels in producing high volumes of disposable lighters with consistent quality. Its energy-efficient operation lowers production costs, making it a cost-effective choice for large-scale manufacturers. However, it may not be ideal for businesses seeking customization options.

Machine 2: Zippo Manufacturing High-Speed Lighter Machine

Zippo’s high-speed machine focuses on speed and efficiency. It is perfect for meeting tight deadlines and handling bulk orders. The machine includes user-friendly controls, allowing you to operate it with ease. Its modular design supports quick adjustments, making it versatile for different production needs. While it offers excellent performance, its higher price point may require careful consideration for smaller businesses.

Machine 3: FlamePro Adjustable Lighter Production System

FlamePro offers flexibility with its adjustable settings. You can customize lighter designs to meet specific consumer demands. The machine integrates smart sensors for precision and error reduction. Its compact size makes it suitable for businesses with limited space. Although it provides excellent customization, its production speed may not match high-volume requirements.

Machine 4: IgniteTech Fully Automated Lighter Maker

IgniteTech’s machine delivers full automation, streamlining your production process. It includes real-time monitoring systems, helping you track performance and address issues quickly. The machine prioritizes safety with built-in protective features. Its high initial cost is offset by reduced labor expenses and increased efficiency. This option works best for manufacturers aiming for large-scale, automated operations.

Machine 5: SparkMaster Compact Lighter Machine

SparkMaster focuses on affordability and compactness. It is ideal for small businesses or startups entering the lighter manufacturing industry. The machine offers basic automation and reliable performance. Its simple design ensures easy maintenance and operation. While it lacks advanced features, it provides a solid entry-level solution for low to medium production volumes.

Comparison Table of Features, Pricing, and Performance

Summary of Key Specifications

Each lighter making machine offers unique features tailored to different production needs. Below is a quick summary of their key specifications:

| Machine Name | Automation Level | Customization Options | Production Speed | Space Requirement | Safety Features |

|---|---|---|---|---|---|

| Societe BIC SA Automatic | High | Low | Very High | Large | Emergency stop, shields |

| Zippo High-Speed Machine | Medium | Medium | High | Medium | Protective shields |

| FlamePro Adjustable System | Medium | High | Medium | Compact | Smart sensors |

| IgniteTech Fully Automated | Very High | Low | Very High | Large | Advanced safety systems |

| SparkMaster Compact Machine | Low | Low | Low | Very Compact | Basic safety features |

This table helps you quickly identify which machine aligns with your production goals and space constraints.

Pricing and Value for Money

When evaluating pricing, you should consider both the upfront cost and long-term savings. IgniteTech’s machine has the highest initial cost but offers significant savings through automation and efficiency. SparkMaster provides the most affordable option, making it ideal for startups. Societe BIC SA and Zippo machines fall in the mid-range, balancing cost and performance. FlamePro stands out for its customization capabilities, offering excellent value for businesses targeting niche markets.

Performance Metrics

Performance varies across machines based on speed, precision, and reliability. Societe BIC SA and IgniteTech excel in high-volume production, ensuring consistent quality. Zippo’s machine delivers impressive speed, ideal for bulk orders. FlamePro focuses on precision and customization, while SparkMaster offers reliable performance for small-scale operations. You should match the machine’s performance to your production needs to maximize efficiency.

Testing Methodology

Criteria for Evaluation

When testing a lighter making machine, you should focus on specific criteria to ensure accurate results. Start by evaluating the machine’s production speed. This determines how quickly it can meet your manufacturing goals. Next, assess its precision. A machine that produces consistent quality minimizes waste and improves customer satisfaction. Durability is another key factor. Machines built with high-quality materials last longer and reduce maintenance costs. You should also consider energy efficiency. Machines that consume less power lower your operational expenses. Finally, safety features must meet industry standards to protect workers and comply with regulations.

Testing Process and Tools Used

Testing a lighter making machine involves a step-by-step process. Begin by setting up the machine according to the manufacturer’s guidelines. Run a series of test batches to measure production speed and quality. Use tools like digital calipers to check the dimensions of the finished lighters. Thermal imaging cameras can monitor the machine’s temperature during operation. Energy meters help you track power consumption. Document every result to identify patterns or inconsistencies. Repeat the tests under different conditions to ensure reliable performance across various scenarios.

Limitations and Considerations

Testing has its limitations. You may not replicate real-world production conditions perfectly. Factors like raw material quality or operator skill can influence results. Additionally, testing a machine over a short period might not reveal long-term durability issues. Consider these limitations when interpreting the results. Always combine testing data with user reviews and expert opinions to make an informed decision.

Each lighter making machine excels in specific areas. Societe BIC SA offers unmatched reliability for large-scale production. Zippo’s machine delivers speed and versatility. FlamePro stands out for customization, while IgniteTech ensures full automation. SparkMaster provides an affordable option for small businesses.

You should assess your production goals and budget. For high-volume needs, choose IgniteTech or Societe BIC SA. For startups, SparkMaster offers a cost-effective solution. Always prioritize safety, efficiency, and long-term value when making your decision.

FAQ

What is the lifespan of a lighter-making machine?

The lifespan depends on the build quality and maintenance. High-quality machines often last 10+ years with proper care and regular servicing.

How do you maintain a lighter-making machine?

Clean the machine regularly, lubricate moving parts, and inspect for wear. Follow the manufacturer’s maintenance schedule to ensure optimal performance and longevity.

Can you customize lighters with these machines?

Yes, machines like FlamePro allow customization. You can adjust settings to create unique designs, catering to specific consumer preferences or niche markets.